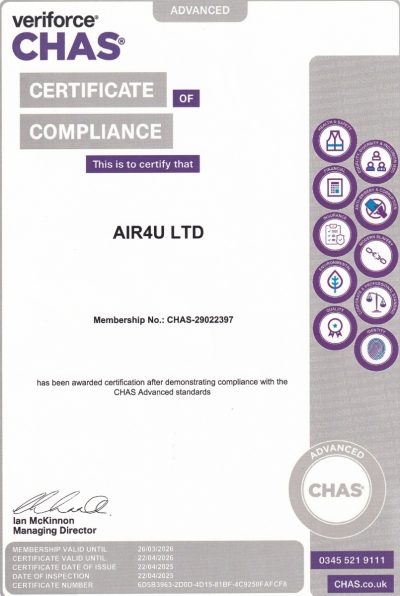

CHAS Advanced Accreditation 2025-2026

AIR4U Ltd are pleased to announce that we have achieved CHAS Advanced Accreditation for another year!

We continue to work hard to improve as a Company and continually strive to maintain and provide a safe environment for our staff and customers.

To achieve our accreditation, CHAS checked important issues, such as:

- Health and Safety

- Equal Opportunities and Diversity

- Quality Management

- Environmental Management

- Continuous Professional Development for our Staff

- Anti-bribery

- Modern Slavery

- Insurance, Financial, Corporate & Professional Standing.

If you would like more information, please follow this link to send us an email: sales@air4ultd.co.uk

Does your Compressed Air System have a leak?

Leaks in the compressed air supply of your production are responsible for unintentional compressed air loss. This leads to higher energy consumption and thus, increasing your energy costs and CO2 emissions. As energy costs are increasing again, any help with reducing expenditure is always a bonus!

Air4u Limited can offer a Leak Detection Test to provide a written report in a clearly understood and actionable format.

With the METPOINT CID leak management system, we can find, log and cost air leaks, so you can prioritise remedial work required to reduce your energy cost. It operates without interupting plant operation, reaching system areas that are hard to access, and locates all air leaks. The leak detector uses ultrasound to find even distant leaks. To do this, we walk systematically along the compressed air lines and use headphones to hear whether we are approaching a leak.

The tester carries out an on-board analysis to pinpoint the exact source of the leak and the exact size of the leak, in litres/minute. Every leak found is tagged and logged. Each tag will carry an identification number, so that when you get the report, it is easy for you to see the location and severity of the leak. We can also take pictures of the leak to pinpoint it for accuracy.

The report will show the leak location, photographs and tag number, as well as useful information like the severity and cost of the leak.

If you have a schematic of your system available, such as a Written Scheme of Examination, it will make our work so much easier!

Best practice advice is that the percentage of compressed air lost to leakage should be less then 10% of your total compressed air production. We recommend that your system is checked for leaks at least once a year. This proactive approach should enable you to keep a tighter control on the system and potential energy wastage.

Air4u Limited can arrange for an experienced engineer to visit you site with our state-of-the-art METPOINT CID leak management system.

For more information or to book a test, please call 01903 257117 or email enquiries@air4ultd.co.uk

To find out more about Written Schemes of Examinations, please check out https://www.air4ultd.co.uk/what-is-a-written-scheme-of-examination-wse/

Are you compliant to Breathing Air Quality Standards?

Is the air from your Compressor safe to breathe? Did you know that you can test your Breathing Air Quality?

The purpose of periodically testing air quality is to make sure that the control measures you have in place are delivering the air quality required. BS EN 12021 states: 'Compressed Air for breathing apparatus shall not contain any contaminants at a concentration which can cause toxic or harmful effects'.

All employers have a duty of care to their staff to ensure that the breathing air supplied by their equipment is safe to breathe.

COSHH regulations require a maximum interval of three months between tests of breathing air systems. BS EN 1221 stipulates minimum quality standards for breathable compressed air. This covers levels of oxygen, carbon monoxide, carbon dioxide, lubricants, water, other types of contaminents and odour.

The purpose of the test is to make sure that the control measures put in place, such as inline filters, are delivering the air quality required by BS EN 12021:2014, which sets the following limits for breathing air testing:

- Oxygen must be at 21% ± 1%.

- Carbon monoxide must be as low as possible and must not exceed 5 ppm.

- Carbon dioxide must not exceed 500 ppm.

- Oil mist and vapour must not exceed 0.5 mgm-3

- Odour/taste - without significant odour or taste.

- Water (liquid) – 290 mgm-3 at 5 bar and 20oC.

In addition, the compressed air quality testing must show a dew point low enough to prevent condensation and freezing. The dew point must be at least 5% below the lowest temperature that the operators use and store the equipment. Furthermore, the dew point must not exceed -11oC where the conditions and storage are unknown.

Whatever your needs, our team are happy to guide you through whatever your industry requirements are and will provide the most suitable solution. We can provide a worry-free programme for a certified Breathing Air Testing service, carried out by our trained engineers. Once the test is completed, we can issue you with a Test Result Certificate to prove your compliance to the relevant authorities.

If you would like to find out more or have a free quotation, please follow this link to send us an email: sales@air4ultd.co.uk

SafeContractor approved for another year

Air4u Limited are proud to announce that we are SafeContracter Approved for another year.

We continually strive to maintain and provide a safe environment for our staff and customers. Using SafeContractor provides us with a system to check that we have all the relevant policies and procedures in place and that they are up to date.

To achieve our accreditation, SafeContractor checked important issues, such as:

- Health and Safety

- Equal Opportunities and Diversity

- Quality Management

- Environmental Management

- Continuous Professional Development for our Staff

- Anti-bribery

- Modern Slavery

- Risk Assessments

- Method Statements

The staff have done a fabulous job ensuring that everything is in place over the year to ensure that we provide a safe environment for everyone.

Air4u Limited ISO9001 Accredited

Air4u Limited are proud to announce that we are ISO9001 Accredited for another year.

Following an audit at the beginning of December 2024, it has been confirmed that we passed our ISO9001 Certification Audit, with no recommendations.

Well done to our staff for their hard work over the year, maintaining the high standards required.

2024 Christmas & New Year Opening Times

Please note our 2024 Christmas and New Year Opening Times:-

Monday 23rd December 8:00am – 4:00pm

Christmas Eve (24th December) 8:00am – 12.00pm

Christmas Day Closed

Boxing Day Closed

Friday 27th December Closed

Saturday 28th December Closed

Sunday 29th December Closed

Monday 30th December Closed

New Years Eve Closed

New Years Day Closed

Thursday 2nd January 8:00am – 4.00pm

During the shutdown period we will have engineers on call

TEL: 01903 257117 option 2

We are a 2024 Avetta Safety Star

We are honoured to receive recognition from @Avetta for being a 2024 Safety Star recipient, celebrating our safety performance score.

Maintaining rigorous safety standards is fundamental to our mission. We are proud to maintain the highest safety standards alongside partners who share our values, proving that excellence in safety is not just a goal, but a daily practice.

Thank you to our employees and all the people we work with, who make this safety record possible through their vigilance and commitment.

What is a 'Written Scheme of Examination' (WSE)?

A Written Scheme of Examination (WSE) is a legal document required prior to use of Pressure Systems.

Under the Pressure Systems Safety Regulations 2000, you are required to demonstrate that you know the safe operating limits of your pressure systems, and that the systems are safe under those conditions.

Users/owners of a system that contains a relevant fluid and at least one pressure vessel exceeding 250 bar/litres must BY LAW have a suitable Written Scheme of Examination in place written by a 'competent person', before the system is operated.

Once the Written Scheme has been drawn up, you also need to ensure that the pressure system is actually examined. It will then be established how often these examinations are required.

The WSE must remain relevant to the pressure system it relates to and therefore, requires periodic reviews. Frequency of the reviews may vary depending on the competent person.

A WSE can cost anything from a few hundred pounds upwards, depending upon the type, number and complexity of equipment being examined and the schedule of parts included in the WSE.

While this may sound expensive, the costs of not having a WSE are far more severe.

A compliant WSE is not just a compliancy exercise, but a vital part in ensuring the safety of your plant and workers.

If a serious or fatal accident were to occur, which is possible due to the volatility of pressure equipment, you would be liable and could face prosecution and imprisonment under the Health and Safety Offences and Corporate Manslaughter Guidelines.

For more information, please see the Health and Safety Executive leaflet https://www.hse.gov.uk/pubns/indg178.pdf which can be downloaded.

If you require further advice, please call 01903 257213 or please follow the link to send us an email at : sales@air4ultd.co.uk

Another year as a Member of BCAS (British Compressed Air Society)

Air4u Limited is a member of BCAS (British Compressed Air Society) for another year.

We continue to be committed to providing the best possible service to our customer, and to using our knowledge to give our customers the best advice we can offer.

So who are BCAS (British Compressed Air Society) and what do they do?

Founded in 1930, the British Compressed Air Society is the only UK technical trade association open to manufacturers, distributors and end users of compressors, vacuum pumps, pneumatic tools and allied products. Their role is to provide unbiased advice on legislation, technical standards, education, compliance, safety and environmental matters that affect suppliers and users of compressed air and vacuum systems.

BCAS plays a crucial role in driving progress in the compressed air industry. In addition, BCAS plays an important role in upholding standards and advising its members about changing legislation and standards to ensure compliance and safety within the industry.

It is an independent source of advice and technical help to ensure that compressor equipment, its installation and maintenance is energy efficient, compliant and safe.

Why is Air Compressor Maintenance essential?

Air4u Group believe compressed air maintenance is essential. Correct maintenance helps to ensure the efficient and reliable operation of various industrial and commercial processes that rely on compressed air. Like any mechanical equipment you may have, your air compressor needs to be serviced regularly to maintain its performance, reliability and longevity.

Proper maintenance is essential to ensure that your air compressor operates efficiently, maintains its performance, and stands the test of time. Routine maintenance can help prevent costly breakdowns and downtime, enhancing overall productivity and minimizing disruptions in production schedules. By replacing worn-out components, cleaning filters, and monitoring oil levels, maintenance safeguards the compressor's performance and safeguards against potential safety hazards.

Air compressors play a crucial role in various industries, from automotive to manufacturing, providing the power needed for multiple applications.

Air Compressors work quite hard for long periods of time. They absorb a huge amount of power and give off a large amount of heat. An air compressor has several parts that must be maintained to ensure they work properly. A compressor needs to have its oil changed, its filters cleaned and its after cooler inspected.

Signs Your Air Compressor Needs Maintenance:

- Reduced Performance.

- Increase in Energy Consumption.

- Unusual Noises.

- Vibration.

- Excessive Heat.

- Oil Leaks.

- Air Leaks.

- Inconsistent Operations.

- Dirty or Clogged Air Filters.

- Unusual Odors.

Annual Service Contract / Air Compressor Maintenance Plan

Having an air compressor maintenance plan is a structured approach to ensure the reliable and efficient operations of air compressors in industrial and commercial settings. Every air compressor comes with a user manual provided by the manufacturer. This manual is your go-to resource for understanding your compressor's unique specifications and maintenance requirements involving scheduled tasks and inspections to prevent breakdowns and prolong the equipment’s life span. A well-designed maintenance plan includes regular checks of critical components such as filters, belts, hoses, lubrication systems, and electrical connections. It also incorporates routine oil changes, cleaning, and calibration to maintain optimal performance. By implementing an air compressor maintenance plan, businesses can minimize downtime, reduce energy costs, ensure safety, and protect their investment in this essential equipment, ultimately contributing to more efficient and cost-effective operations.

For more information, please see https://www.air4ultd.co.uk/maintenance/

If you wish to find out any further information or would like to book a service, please follow the link to send us an email at sales@air4ultd.co.uk